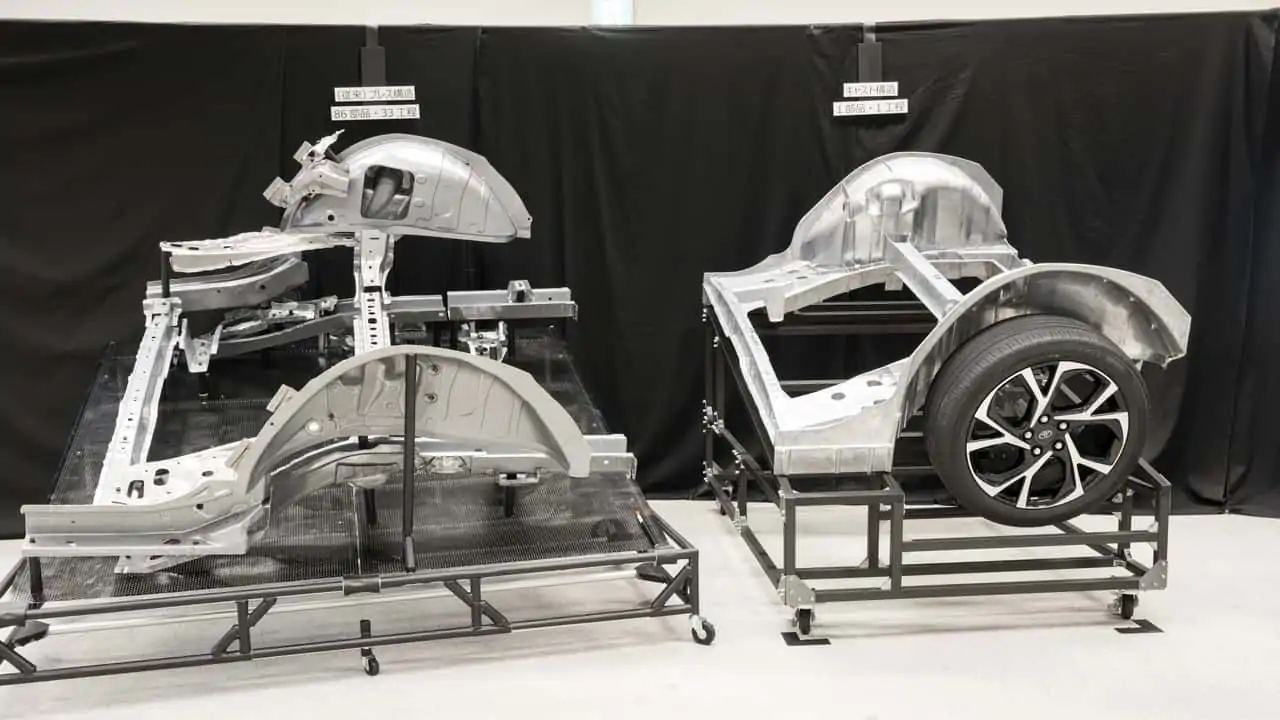

Gigacasting is a manufacturing process that uses high-pressure die-casting machines to produce large, complex metal parts. It is a relatively new technology, but it has the potential to revolutionize the manufacturing of electric vehicles (EVs).

One of the key benefits of gigacasting is that it can reduce the number of parts required to assemble an EV. For example, Tesla uses gigacasting to produce a single front underbody casting that replaces 171 individual parts. This not only simplifies the assembly process, but it also reduces the weight of the vehicle.

Another benefit of gigacasting is that it can improve the strength and durability of EV parts. Gigacast parts are made from a single piece of metal, which eliminates the need for welds. This makes the parts stronger and more resistant to damage.

Gigacasting is still in its early stages of development, but it has the potential to transform the future of EV manufacturing. By reducing the number of parts required to assemble an EV, gigacasting can simplify the assembly process and reduce the cost of EVs. Additionally, gigacasting can improve the strength and durability of EV parts, which can lead to longer vehicle life spans.

Here are some of the key benefits of gigacasting for EV manufacturing:

- Reduces the number of parts required to assemble an EV

- Simplifies the assembly process

- Reduces the weight of the vehicle

- Improves the strength and durability of EV parts

- Leads to longer vehicle life spans

Here are some examples of how gigacasting is being used in EV manufacturing today:

- Tesla uses gigacasting to produce the front and rear underbody castings for its Model 3 and Model Y vehicles.

- Volkswagen is using gigacasting to produce the front and rear underbody castings for its upcoming ID.Buzz van.

- Ford is using gigacasting to produce the structural battery pack enclosure for its upcoming F-150 Lightning electric pickup truck.

Gigacasting is a transformative technology that has the potential to revolutionize the manufacturing of electric vehicles. By reducing the number of parts required to assemble an EV, simplifying the assembly process, and improving the strength and durability of EV parts, gigacasting can make EVs more affordable, reliable, and sustainable.