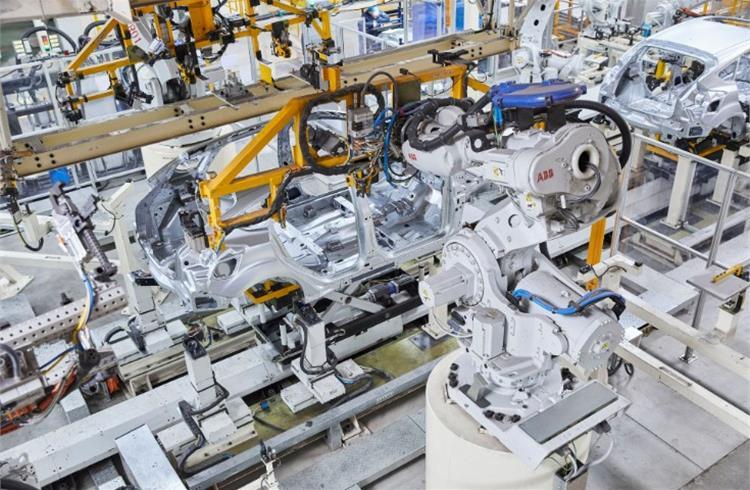

ABB, a Swiss-Swedish multinational corporation specializing in robotics, power, and automation technology, has launched a new range of robots specifically designed for electric vehicle (EV) manufacturers. The new robots are expected to help EV makers improve efficiency, productivity, and quality while reducing costs.

The new ABB robots are part of the company's IRB 5700 and IRB 5720 families. These robots are available in eight variants with payloads ranging from 70 to 180 kilograms and reaches ranging from 2.3 to 3 meters. The robots are designed to perform a variety of tasks in EV manufacturing, including:

- Material handling: The robots can be used to move materials such as batteries, motors, and body panels around the factory floor.

- Machine tending: The robots can be used to load and unload machine tools, such as welding machines and painting robots.

- Assembly: The robots can be used to assemble EV components such as batteries, motors, and body panels.

- Inspection: The robots can be used to inspect EV components for defects.

The new ABB robots are equipped with a number of features that make them well-suited for EV manufacturing, including:

- Precision: The robots are capable of high precision assembly and inspection tasks. This is important for EV manufacturing, where quality control is critical.

- Speed: The robots are fast and agile, which helps to improve efficiency and productivity.

- Flexibility: The robots can be programmed to perform a variety of tasks, which makes them adaptable to different EV manufacturing processes.

ABB's new robots have already been deployed at a number of EV manufacturing facilities, including Ola's mega factory in Hosur, Tamil Nadu, India. Ola is using ABB robots to perform a variety of tasks in its battery and motor assembly lines.

The use of ABB robots is helping Ola to improve the efficiency, productivity, and quality of its EV manufacturing operations. Ola is also able to reduce costs by using ABB robots, as robots can perform many tasks that would otherwise require human labor.

Benefits of using ABB robots for EV manufacturing

There are a number of benefits to using ABB robots for EV manufacturing, including:

- Improved efficiency and productivity: ABB robots can perform tasks much faster than humans, which can help to improve efficiency and productivity in the EV manufacturing process.

- Enhanced quality control: ABB robots are capable of performing high precision tasks, which helps to improve the quality of EV components.

- Reduced costs: ABB robots can help to reduce labor costs, as robots can perform many tasks that would otherwise require human labor.

- Improved safety: ABB robots can help to improve safety in the EV manufacturing workplace by automating tasks that are dangerous or repetitive.

Challenges of using ABB robots for EV manufacturing

There are a few challenges to using ABB robots for EV manufacturing, including:

- High initial cost: The initial cost of purchasing and installing ABB robots can be high. However, the long-term benefits of using ABB robots, such as improved efficiency and productivity, can offset the initial cost.

- Complex programming: ABB robots are complex and require skilled programmers to operate them. This can be a challenge for EV manufacturers that do not have the in-house expertise to program ABB robots.

- Maintenance: ABB robots require regular maintenance to ensure that they are operating properly. This can be a cost and time commitment for EV manufacturers.

Conclusion

ABB's new robots offer a number of benefits for EV manufacturers, including improved efficiency, productivity, quality, and safety. However, there are a few challenges to using ABB robots, such as the high initial cost, complex programming, and maintenance requirements.

Overall, ABB's new robots are a valuable asset for EV manufacturers that are looking to improve their operations and reduce costs.

Additional thoughts

The development and deployment of new robots for EV manufacturing is a positive development for the EV industry. Robots can help EV manufacturers to improve their operations and reduce costs, which will make EVs more affordable and accessible to consumers.

The use of robots in EV manufacturing is also creating new jobs in the EV sector. Robots need to be programmed, maintained, and operated, which requires skilled workers. The EV industry is growing rapidly, and the demand for skilled workers is expected to increase in the coming years.

The development and deployment of robots for EV manufacturing is a sign of the progress that is being made in the EV industry. Robots are helping to make EVs more affordable, accessible, and sustainable.